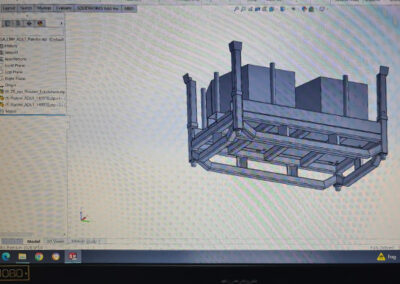

Design and prototypes

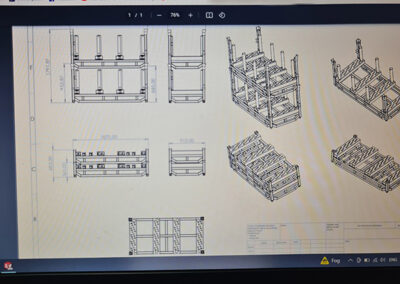

Manufacturing projects go through many stages from initial concept to finished product.

Product design, prototyping and assembly.

From concept to realization

It all starts with an initial idea, but remember, just because you have a concept in mind doesn’t mean the project can be easily realized. This is where we perform.

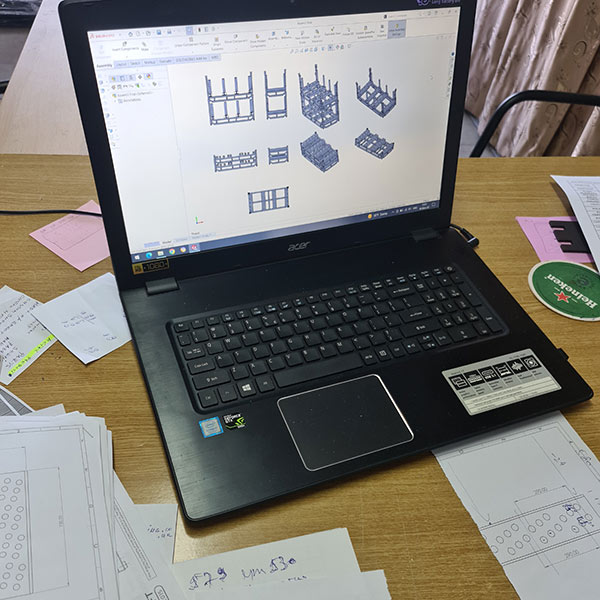

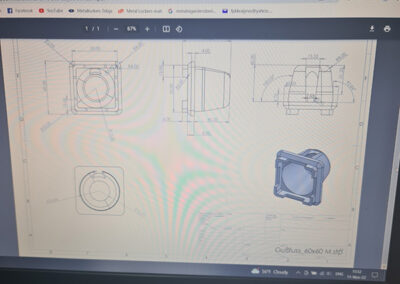

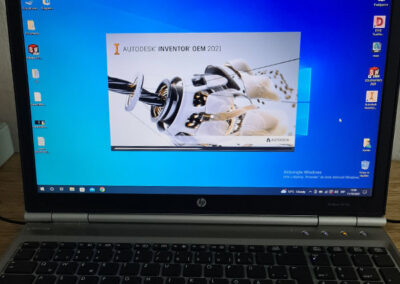

Generally, our customers provide us with everything they can to illustrate their ideas, from hand-drawn plans to engineering drawings. We usually get a concept rather than a drawing, but we are happy to go with what our customers have available. We use Inventror and Solid Works software which means we can accept files from most software systems.

One of our greatest strengths is our ability to solve problems. Many of our clients work with us in this area, they have something they want to achieve but don’t know how.

Combining our experience and long-term expertise, we are always able to find a solution to a problem.

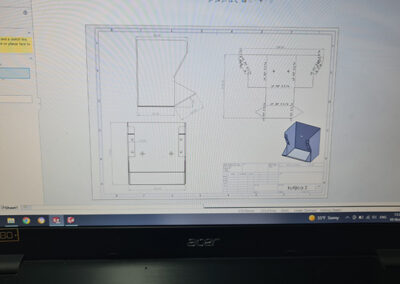

Once we have completed the initial design phase and everyone involved in the project has signed off on our technical specifications, we move on to the exciting part-production. This is where our product comes to life.

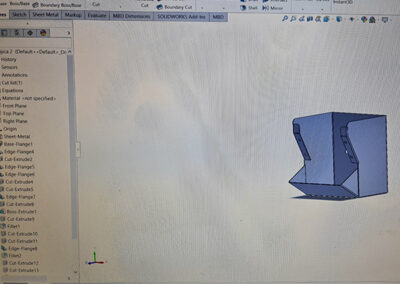

SHEET METAL PRODUCT offers fast sheet metal prototyping for various industrial applications.

Our machining capabilities include laser cutting, CNC punching, drilling, turning, MIG and TIG welding, as well as plasticizing one-off prototype sheet metal products.

With all the production capacity available to us in one place, we can offer an unsurpassed turnaround on one-off prototypes.

Challenge SHEET METAL PRODUCT to produce your one-off metal prototype and see how quickly we can have your design in front of you.